Isidibanisi, esaziwa ngokuba yi-header okanye i-wafer, sisidibaniso esihlala kwibhodi yesekethe eprintiweyo kwaye kufuneka sithengiswe kwizikhonkwane zesekethe.

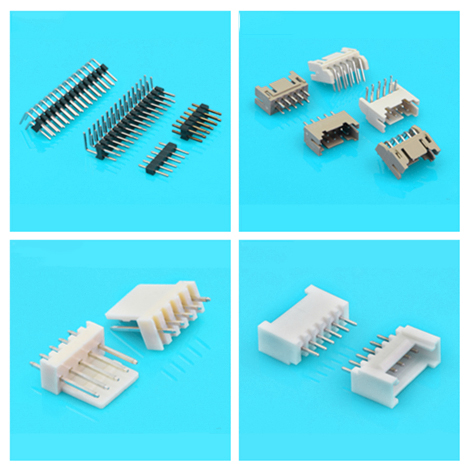

Izikhonkwane ezixhaphakileyo zezikhonkwane zezi: akukho siseko sokugquma (umzekelo: isakhiwo senaliti yomqolo), isiseko sokugquma (uhlobo lwe-wafer oluqhelekileyo), uhlobo lwe-friction lock.

Isibambi sephini yesiqhagamshelo singokweplastiki ekhethekileyo yendawo yokushisa okuphezulu, kwaye kufuneka ibe nokumelana nokushisa okuphezulu.Umzekelo, isibambi senaliti esisetyenziselwe ukudibanisa i-surface mount welding siyakudityaniswa ngezixhobo ze-welding reflow, kwaye iqondo lobushushu liya kufikelela malunga ne-265 °;Enye into yokuba uhlobo lwephini kufuneka ludityaniswe ngesixhobo sokuthengisa amaza, kwaye ukumelana nobushushu kufuneka kufikelele malunga ne-230 °.Ukuba ubushushu beplastiki ayikwazi ukufikelela kwinkqubo welding kuya kuchaphazela ukusetyenziswa ngokuqhelekileyo deformation yesakhiwo.

Izikhonkwane zokudibanisa zisebenzisa izinto zeplastiki ekrwada: Inayiloni, ipolyester, inayiloni, ubushushu obuphezulu - PBT, ipolyester - PCT, PPS, LCP, njalo njalo, umbane ohlukeneyo kwinkqubo yokubumba, ubude bokuhamba kwezinto zeplastiki, ukucutheka, ukunyanzeliswa kwamanzi, ukwandiswa komgca. i-coefficient yahlukile, kuphuhliso lokungunda lweplastiki lunento eninzi yokwenza nezinto ezisetyenzisiweyo kubalwa ngokuchanekileyo.

Ixesha lokuposa: Dec-16-2021